Derived from forest residues and timber processing, wood pellets offer higher purity than raw wood or coal. By eliminating non-combustible debris, this fuel provides a higher heat-to-weight ratio, directly reducing energy costs for consumers.

| Feature | Specifications |

| Product Size | 6mm – 12mm Finished Pellets |

| Output Capacity | 1 – 30 Tons per Hour (T/H) |

| Material Input | High-density chips from various wood species |

| Primary Uses | Energy production, Heating, Agriculture, and Livestock |

We offer complete, turnkey biomass pellet production lines, covering everything from initial design to final installation. Our systems are capable of processing wood, sawdust, rice husk, EFB, grass, or organic fertilizer, with capacities ranging from 1–100 TPH.

This modular chipper features an integrated infeed trough and discharge conveyor for high-capacity biomass processing. It is designed for seamless integration into automated pellet production lines.

This industrial hammer mill grinds wood chips and biomass into fine, uniform powder (3–5mm). Its heavy-duty rotor ensures high-capacity throughput and consistent material quality for pellet production.

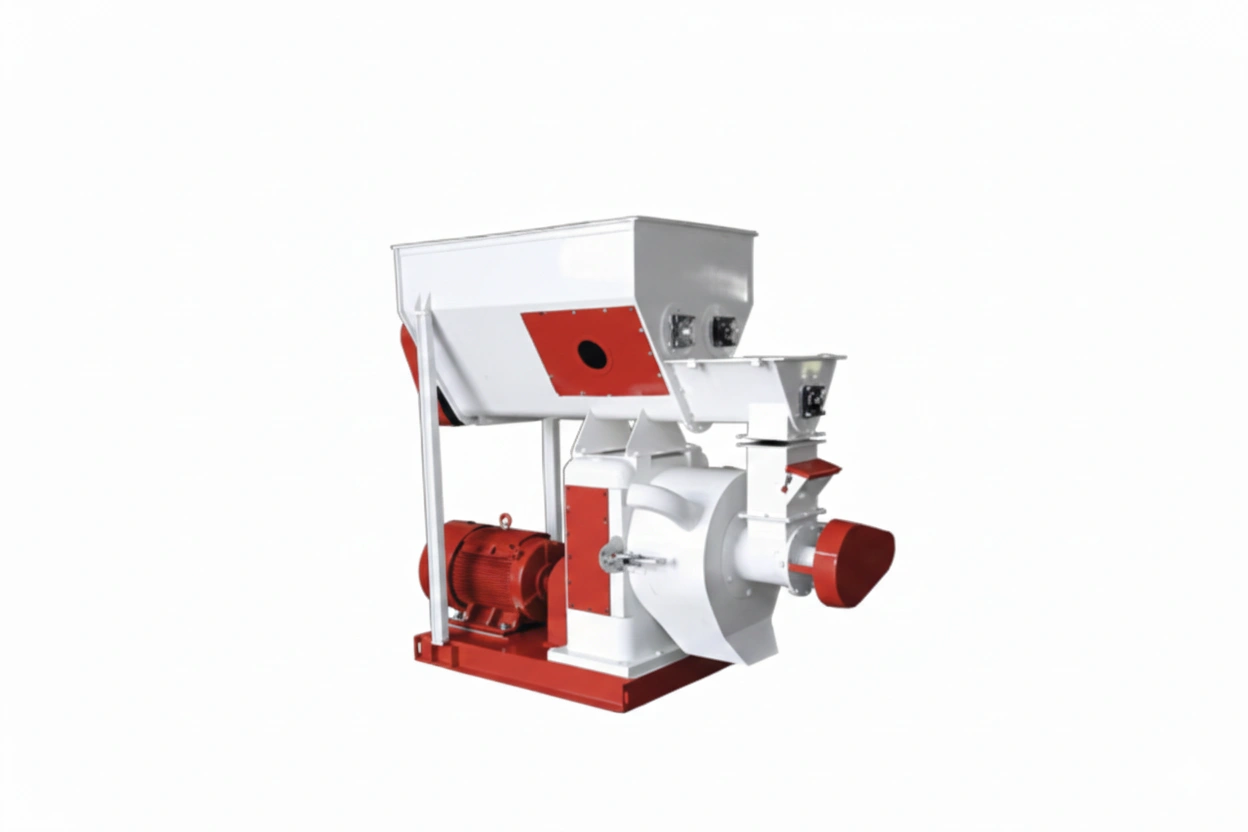

As the core of the production line, this ring die pellet mill compresses biomass powder into high-density fuel. Built for 24/7 industrial use, its precision drive and heavy-duty rollers ensure consistent pellet quality and long-term durability.

Our modular pellet production lines are fully customizable to fit your specific raw materials, site limitations, and process requirements. From storage to final packaging, we provide engineered solutions designed for maximum ROI—whether you need a single component or a complete turnkey system.

Turning ‘impossible’ into your competitive advantage. We bridge the gap between ambitious concepts and precision execution, delivering the technical mastery your next big move demands.

near lohianwali, Guj, Pakistan

Saadmughal343@gmail.com

+92300 6408742